Smile, Smart, Speed

고객의 만족을 위하여 최선을 다하는 기업, 정문사이언스입니다.

고객의 만족을 위하여 최선을 다하는 기업, 정문사이언스입니다.

HOME > 회사소개 >소재 및 부속품

HOME > 회사소개 >소재 및 부속품 N Type 156mm Monocrystalline Solar Wafer

The fact that cell technologies featuring the highest efficiencies in industrial production are based on N type Cz-Si wafer is a striking demonstration of why n-type wafers are the most suitable material for high-efficiency solar cells. Going more into details, there are some physical reasons for the superiority of N type versus P type, the most important are:

due to absence of boron, there is no light induced degradation (LID) occurring in p-type Si wafers, due to boron-oxygen complexes

as N type Si is less sensitive to prominent metallic impurities, in general the minority carrier diffusion lengths in n-type Cz-Si are significantly higher compared to p-type Cz-Si

N type Si is less prone to degradation during high temperature processes such as B-diffusion.

1 Material properties

Property | Specification | Inspection Method |

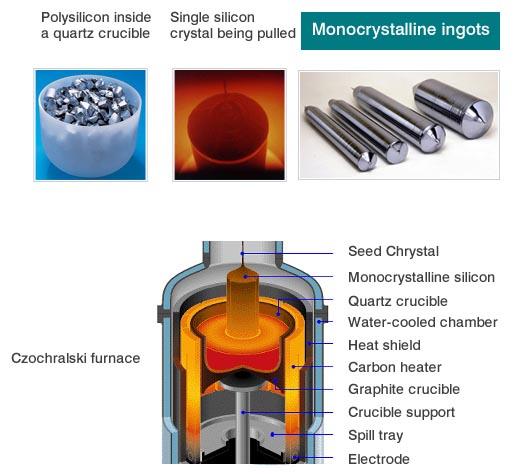

Growth method | CZ | |

Crystallinity | Monocrystalline | Preferential Etch Techniques(ASTM F47-88) |

Conductivity type | N-type | Napson EC-80TPN |

Dopant | Phosphorus | - |

Oxygen concentration[Oi] | ≦8E+17 at/cm3 | FTIR (ASTM F121-83) |

Carbon concentration[Cs] | ≦5E+16 at/cm3 | FTIR (ASTM F123-91) |

Etch pit density(dislocation density) | ≦500 cm-3 | Preferential Etch Techniques(ASTM F47-88) |

Surface orientation | <100>±3° | X-ray Diffraction Method (ASTM F26-1987) |

Orientation of pseudo square sides | <010>,<001>±3° | X-ray Diffraction Method (ASTM F26-1987) |

2 Electrical properties

Property | Specification | Inspection Method |

Resistivity | 0.2-2.0 Ω.cm 0.5-3.5 Ω.cm 1.0-7.0 Ω.cm 1.5-12 Ω.cm Other resistivity | Wafer inspection system |

MCLT (minority carrier lifetime) | ≧1000 μs(Resistivity > 1 Ωcm) | Sinton transient |

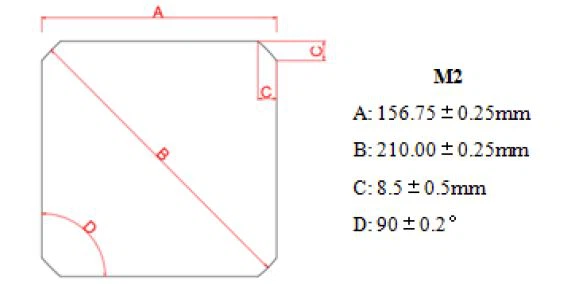

3 Geometry

Property | Specification | Inspection Method |

Geometry | Pseudo square | |

Bevel edge shape | Round | |

Wafer size (Side length*side length * diameter | M0: 156*156*ϕ210 mm M1: 156.75*156.75* ϕ205mm M2: 156.75*156.75* ϕ210 mm | Wafer inspection system |

Angle between adjacent sides | 90±3° | Wafer inspection system |